The curve briefly explained

T03 + Ca2, standard vs. premium

All curves of a modular pump track are created from the T03 module. These can be linked together as often as desired, depending on the angle of the curve.

Each of these modules is covered with a CA2 curved outer cover.

In the STANDARD version of the Allrounder , the curve modules are made of boat building plywood , as are the other modules of a Modular Pumptrack Allrounder.

The latest generation and an upgrade option is the All-rounder PREMIUM, with curve modules made of galvanized steel and external covers made of fiberglass.

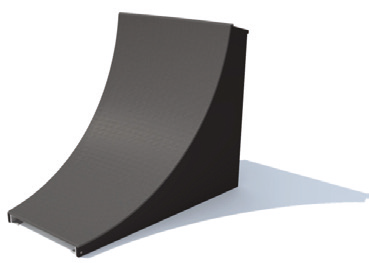

Module T03 Standard made of marine plywood

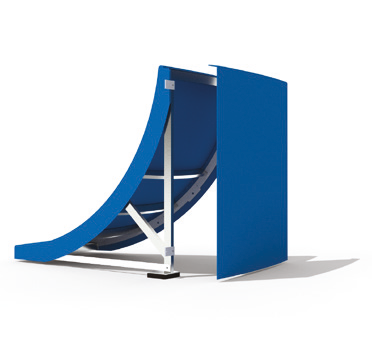

Premium Upgrade:

Consider the PREMIUM curve module!

Galvanized Steel substructure, fiberglass riding surface with additional sound insulation

Choose Premium because...

- Efficient assembly and dismantling

- 100% Galvanized steel frame

- Removable Legs

- Fiberglass rear enclosure

- Low volume and weight (up to 6kg lighter per module!)

- more compact in transport and storage

- Extra durability

- Available in all RAL colors

- Only a small additional cost per module

Why steel and fiberglass?

The curve modules take the brunt of the forces that put lasting strain on the materials and create the most noise.

- Steel and fiberglass are extremely resilient to extraordinary forces generated by the riders and very resistant to all weather conditions.

- Steel and Fiberglass is also much better than wood, plastic, and other materials at absorbing noise and sound vibration generated by wheeled sports equipment.

The more curve elements

...in relation to waves, the more challenging the modular pump track is to ride