TÜV, ISO, Safety Zone - Because that's important to us

Security & Certificates

Safe driving fun

This motto characterizes our modular pump track from development to production, assembly and of course use. Even after the modular pump track has been installed, our international team remains available to ensure safe use of the system for many years.

Tüv certification

The Modular Pumptrack is TÜV (EN14974) and ISO (ISO 14001:2015)certified. We will be happy to send you the certificates if required!

Let's take a closer look...

NEW: The fall height is lower than 60cm and therefore corresponds to the standard, so that no further fall protection measures are necessary.

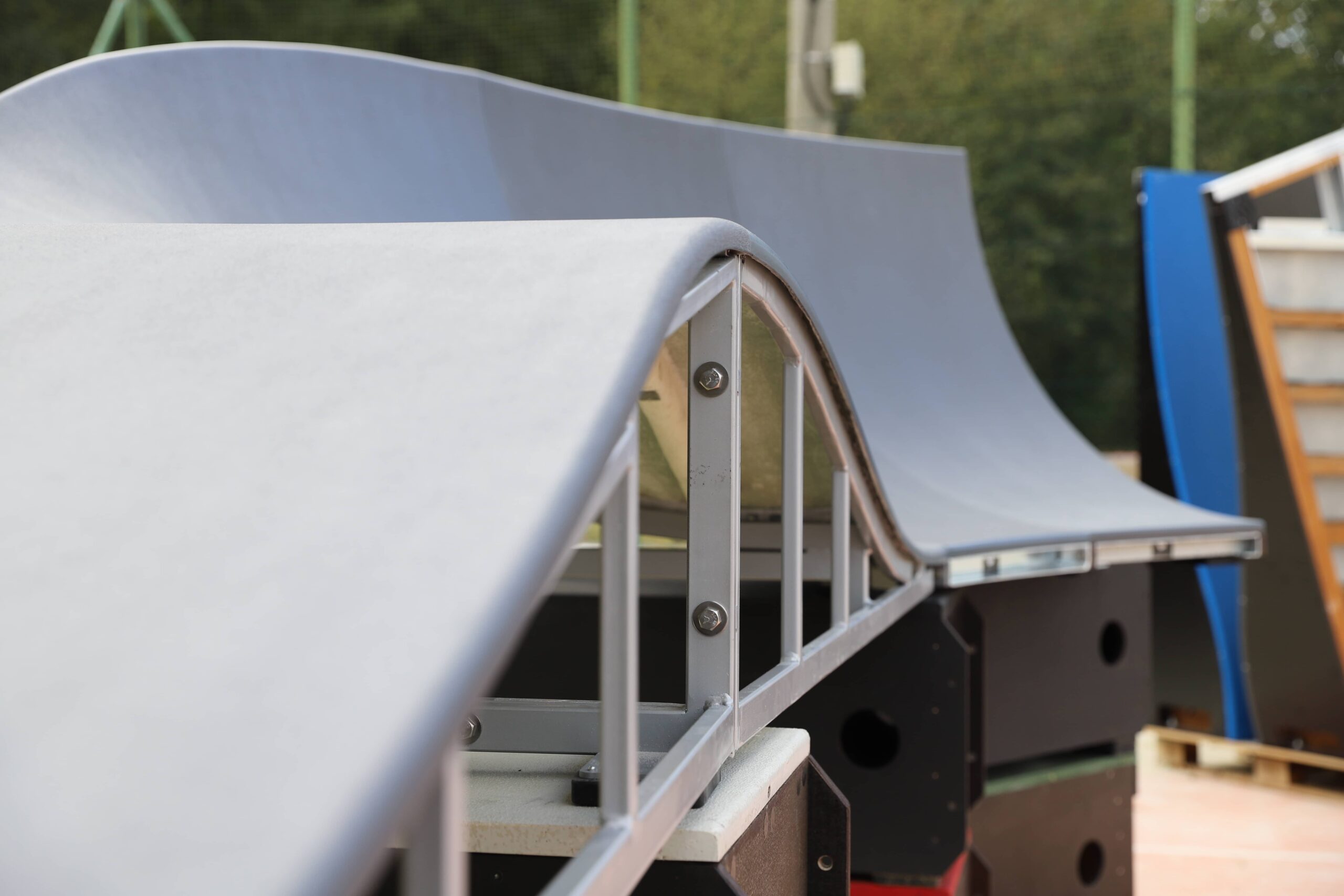

1 of 6 Non-slip surfaceThe high-strength and reinforced fiberglass tread with all-weather grip is suitable for all wheels and is non-slip. The surface is repairable and screws are only attached to the outside and underside, so there are no potential disturbers on the tread

2 of 6 Controlled drivingSince your own weight and ability dictate your speed, riding the roller sports equipment is very controlled and it is almost impossible to overestimate. Roll-out zones can also slow down the pace

3 of 6 Rounded edgesRisk of injury on sharp edges is eliminated thanks to the rounded design

4 of 6 Proven designThe design specifies the jump angle, take-off and landing zone, ensures the perfect flow and remains consistently good without any signs of wear!

5 of 6 Robust boat building plywoodNothing can break away, nothing can get moldy: the boat building plywood is robust and effectively treated to protect it from water and insect infestation. Hard rubber feet also prevent direct contact with the floor

6 of 6Development

PARKITECT® is the inventor of the modular pump track and has been the world market leader since 2010. The Modular Pumptrack has been further developed over the years through continuous versions and today meets the highest safety standards of TÜV and ISO certifications.

production

Every order goes through a modern production line, equipped with 5-axis CNC milling, drilling and grinding machines, painting systems, metal construction and many special facilities. When a module comes off the assembly line, quality checks are carried out before an individual serial number ensures tracking even after years.

transport

After production is completed, the individual modules are combined into one order and stored on pallets until shipping. The goods are always transported by the same shipping company, which is familiar with the careful handling of the pallets and delivers from the factory by truck directly to the destination throughout Europe.

Assembly

We attach great importance to correct and reliable installation. For this reason, we work with local assembly partners who are specially trained to set up our modular pump tracks. A safety distance of approx. 2 meters from other obstacles is always maintained.

use

To ensure that the fun on the modular pump track is safe and lasting, users must follow a few rules. With every modular pump track we send a user information board where all the rules are listed in an understandable way.

service

Our international team knows the answer to all Modular Pumptrack questions. We are available to provide advice and support before, during and after the purchase.

Extra liability insurance?

If the location is at a playground, sports field or school, the operator usually already has insurance